Kanban - Task Management app for iPhone and iPad

Kanban is an Agile method based on the Toyota Production Method with four principles:

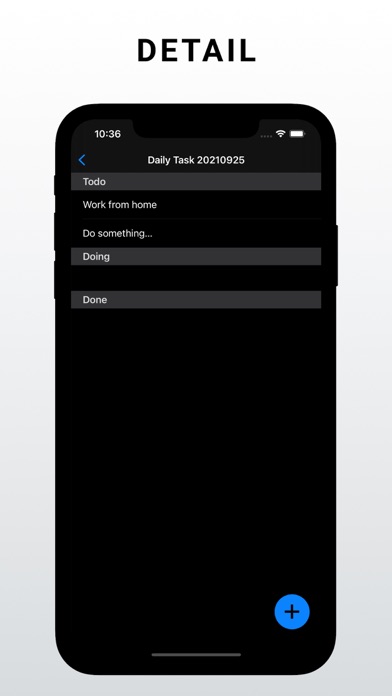

- Visualize the work

Kanban tables are tools for visualizing work. Kanban tables include columns corresponding to the status of the job. Each job when in any state is placed in the corresponding column. We can use a physical board or a Kanban software like Kanban - Todo list.

- Limit your work (Limit WIP - Limit Work In Progress)

The amount of work being done simultaneously in each status needs to be limited. This principle helps limit unfinished things in the process, thereby reducing the time each job passes through the Kanban system. WIP limit principle also helps the team work focused, avoiding waste due to having to switch between different jobs.

- Focus on the work flow

Applying the WIP limit principle and developing group-oriented policies enables the team to optimize the Kanban system to improve smooth working flow.

- Continuous improvement

The team measures the effectiveness by tracking quality, time of making products, etc. from there to analyze and test to change the system to increase the effectiveness of the group.